Steel Road Plates vs. Composite and Plastic Road Plates

When it comes to construction and roadworks, choosing the right road plates is essential to the success and smooth operation of your project. These unique products help to provide a temporary road surface and keep traffic moving. However, when it comes to choosing between steel road plates and composite or plastic options, which is the right one for you?

In this latest article, we thought we would explore the unique properties and benefits, allowing you to make an informed decision on which solution you should use.

What Are Steel Road Plates?

First things first, what exactly are steel road plates? These heavy-duty and durable plates offer unmatched strength, making them perfect for long-term projects. Whether it’s covering a trench, creating a stable path for heavy vehicles, or ensuring pedestrians can safely cross a work zone, steel road plates are a versatile solution.

Properties of Steel Road Plates

Steel plates for road construction are all about strength and durability. Made from AS3678-250 Grade Carbon Steel, they are incredibly tough and capable of handling heavy loads without buckling. Steel road plates are also available in a variety of sizes, depending on the project requirements. At RPM Hire, our options all come in durable 25mm thick plating and sizes ranging from 1.2m x 1.2m up to 3.0m x 1.8m.

What Are the Advantages of Steel Road Plates?

There is a wide array of benefits to utilising steel road plates. The biggest is their longevity, with these plates capable of lasting many years in the toughest conditions. They are also very strong, making them ideal for use in high-traffic areas or where heavy machinery is going to be used.

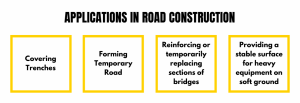

Applications in Road Construction

Steel plates for road works are a very popular choice thanks to their versatility, but they are the go-to choice for heavy-duty and long-term projects. Some of the most common uses include:

- Covering trenches

- Forming temporary roads

- Reinforcing or temporarily replacing sections of bridges

- Providing a stable surface for heavy equipment on soft ground

Steel Road Plates vs Composite Road Plates

How do steel plates for road construction compare to those made of composite materials? These are a relatively new option on the market in comparison, with the plates created from materials such as fibreglass, resin and polymers. This makes them very lightweight and much easier to handle and install compared to steel, and despite their light weight, they offer fantastic strength and durability.

The biggest advantage of composite plates is just how easy they are to manoeuvre around your worksite, removing the need for heavy lifting equipment. They also often feature non-slip surfaces, which is an added bonus for wet weather.

Yet, while they are a fantastic choice for a range of situations, they are not suitable for every project. They are not as strong or offer the same level of endurance as steel road plates, so it is important to consider your project requirements.

Steel Road Plates vs Plastic Road Plates

Plastic road plates are another popular choice for roadworks and construction projects. Typically made from High-Density Polyethylene (HDPE), these plates are lightweight and very easy to handle, which makes them a solid choice for temporary or lighter-duty projects.

Just like composite road plates, the plastic options are highly portable and can be quickly and easily installed without the need for heavy equipment. The materials are also highly resistant to corrosion and chemicals, making them ideal in certain environments.

Plastic road plates are not meant for heavy-duty applications, though. They are more suited for pedestrian areas or where only light vehicles will pass over.

Should We Use Steel Road Plates For Road Construction?

Now you know the differences between steel, composite, and plastic road plates, which one is right for your project? When deciding what you need, there are a number of factors you will need to consider, including:

Load Capacity and Project Requirements

When choosing a road plate, the first thing that you will need to factor in is the load capacity. If your worksite is going to have a lot of heavy traffic or heavy machinery operating throughout, then steel road plates are the best solution.

However, if you are only going to need to cover small excavations or in areas of footfall, then plastic or composite options are a lightweight solution.

Installation and Handling

Next, you will then need to consider how easy it is to install and handle your road plates. Steel plates for road works are very heavy and will often require lifting machinery to position into place, whereas composite and plastic options can be manoeuvred into place by hand.

Cost and Environmental Impact

Cost is another factor that you will need to consider. Steel road plates are usually a higher upfront cost, but their durability can make them a cost-effective choice in the long run. Composite and plastic road plates will usually need to be replaced more often in long-term projects, which can increase the costs.

In terms of the environmental impact, steel production and recycling are an energy-intensive process. Composite plates often have a lower carbon footprint during production, but is a challenge to recycle, while plastic has a number of environmental issues around sustainability and recycling.

Choose the Best Road Plates for Your Project with RPM Hire

Choosing the right road plate can help to transform the efficiency and safety of your worksite. Steel road plates offer unmatched strength and durability, making them ideal for heavy-duty and long-term work, while plastic and composite – road plates are lightweight and easier to handle.

Here at RPM Hire, we have a wide range of road plates available, ensuring that no matter your project, you will always be able to find the perfect solution. We pride ourselves on delivering high-quality equipment designed to help you keep your traffic moving.

Want to find out more? Get in touch with our team today who will be happy to help!